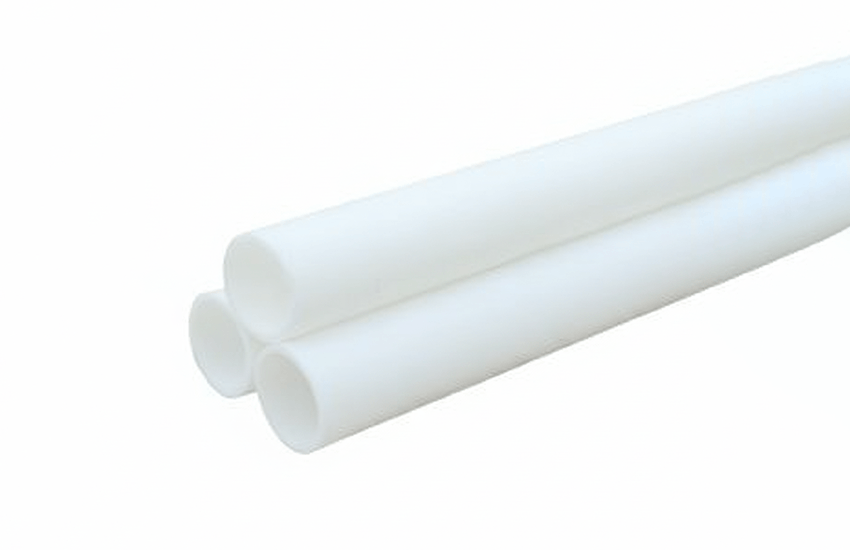

PVDF Round-bar

PVDF Round-Bar

Strong, clean, and corrosion‑resistant rods for demanding parts :

PVDF round bars are chosen when parts must hold their shape, purity, and

strength under chemical exposure, heat, or long service life. Made from

100% virgin Kynar PVDF resin, these offer low permeability, good wear

resistance rods, and stable performance in harsh environments. They are

suitable for machining into components used in chemical handling, water

treatment, electronics, and other high‑purity systems.

Each bar is produced with a controlled diameter and a smooth finish so it

machines well and stays consistent across batches. That makes them

practical for custom parts, spares, or small runs where material quality and

repeatability matter more than low cost alone.

What Makes Our PVDF Round Bars Different :

PVDF round bars may appear similar, but material consistency, density control, and surface quality make a clear difference in performance.

| Features | Our Advantage | |

|---|---|---|

| Material Quality : | Pure Kynar PVDF resin with no fillers or recycled material. | |

| Dimensional Stability : | Controlled diameter tolerance for accurate machining and fabrication. | |

| Surface Quality : | Smooth finish for reduced wear, friction, and contamination risk. | |

| Chemical & Thermal Resistance : | Reliable performance in temperatures from –30°C to +140°C (up to 150°C short-term). | |

| Machinability : | Suitable for turning, milling, drilling, and precision shaping. | |

Key Advantages :

-

Suitable for high-purity, chemically aggressive, and heat-exposed applications.

-

Non‑reactive, non‑leaching, and biologically inert material for high‑purity use.

-

Strong resistance to stress, wear, and environmental exposure.

-

Retains useful strength in both warm and cold operating conditions.

-

Good electrical insulation properties.

-

Long service life with minimal maintenance.

Applications & Industries :

PVDF round bars are used for components that must perform reliably in harsh or contamination-sensitive environments:

-

Chemical Processing : Machined parts, spacers, pump components, anti-corrosion hardware.

-

Semiconductor & Electronics : Insulators, UPW system parts, cleanroom components.

-

Pharmaceutical & Biotech : Hygienic components, contact-safe machined parts.

-

Water Treatment & Desalination : Components for chlorine, ozone, and corrosive fluid systems.

-

Food & Beverage : FDA-compliant parts for non-contact and utility applications.

-

Battery & Lithium Processing : Electrolyte-resistant parts and structural components.

-

General Engineering : Bushings, wear parts, standoffs, mechanical components.

Why Industries Choose Us

Engineering Trust. Delivering Quality

-

Consistent material quality and rod dimensions.

-

Reliable machining behavior and part repeatability.

-

Technical guidance for material selection and component design.

-

Proven field performance in high‑purity and corrosive environments.

Request a Quote

Let’s Build Your Next Project

Our PVDF round bars offer the strength, purity, and chemical resistance

needed for demanding industrial applications.

For sizing, machining guidance, or project-specific support, speak with our

engineering team.