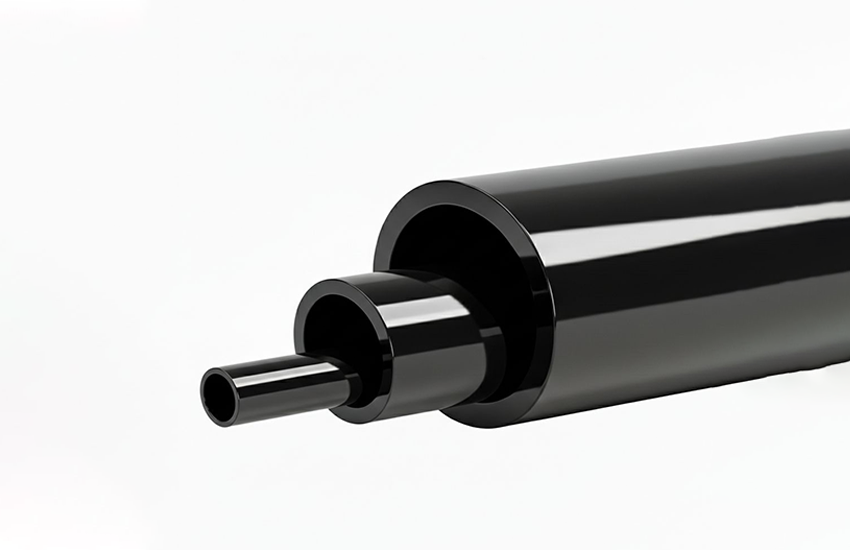

HDPE Lining

HDPE Lining

Durable Corrosion Protection for Industrial Equipment:

HDPE lining is used to protect tanks, vessels, pits, channels, and process

equipment from chemical attack, abrasion, and moisture exposure.

Made from high-density polyethylene, this lining solution provides

excellent toughness, chemical resistance, and long service life in

demanding industrial environments.

HDPE is non-reactive and resistant to a wide range of acids, alkalis, salts,

and industrial fluids. It is commonly applied over different base materials to

extend equipment life, including

MS (Mild Steel), SS (Stainless Steel), and

FRP substrates.Configurations such as MS + HDPE lining, SS + HDPE lining, and FRP + HDPE lining are widely used where structural strength and corrosion resistance are both required.

Its low moisture absorption and high impact strength make HDPE lining suitable for continuous operation in wet, abrasive, or chemically aggressive conditions.

What Makes Our HDPE Lining Different :

HDPE lining performance depends on material quality and thickness uniformity. We focus on controlled fabrication and consistent application to ensure reliable long-term protection.

| Features | Our Advantage | |

|---|---|---|

| Material Quality : | High-density polyethylene with excellent toughness and durability. | |

| Substrate Compatibility : | Suitable for MS, SS, and FRP equipment. | |

| Uniform Thickness : | Even lining coverage, for predictable corrosion protection, contamination, and product degradation. | |

| Chemical Resistance : | Withstands acids, alkalis, salts, and industrial fluids. | |

| Abrasion Resistance : | Performs well in slurry and wear-prone environments. | |

Key Advantages :

-

Excellent resistance to corrosion and chemicals.

-

High impact and abrasion resistance .

-

Low water absorption and moisture resistance.

-

Non-reactive, contamination-free surface.

-

Long service life with reduced maintenance.

Applications & Industries :

HDPE lining is widely used where durability and corrosion protection are critical :

-

Chemical Processing : Tanks, sumps, containment pits.

-

Water & Wastewater Treatment : Channels, clarifiers, chemical handling areas.

-

Mining & Minerals : Slurry tanks, chutes, wear surfaces.

-

Power & Utilities : Cooling water systems, process areas.

-

Industrial Storage : Chemical storage vessels and bins.

-

Infrastructure & Civil Works : Drainage channels, exposed concrete protection.

HDPE Lining :

Why Industries Choose Us

Engineering Trust. Delivering Quality

-

Consistent HDPE material quality.

-

Controlled lining thickness and surface finish.

-

Reliable performance in abrasive and corrosive environments.

-

Technical support for lining design and application.

-

Proven field use across industrial sectors.

Request a Quote

Let’s Build Your Next Project

If your equipment requires tough, abrasion-resistant, and chemically

stable protection, our HDPE lining solutions offer a dependable and

cost-effective option.

For specifications, application guidance, or project support, connect with

our technical team.