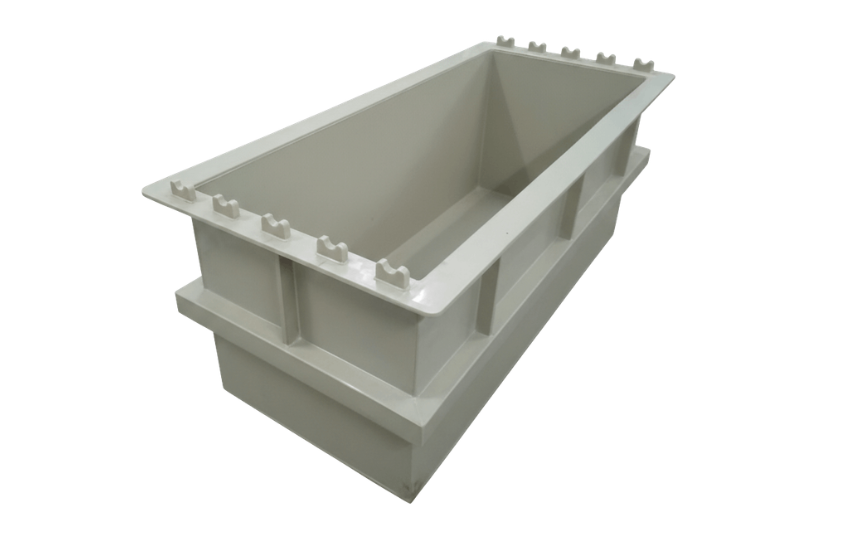

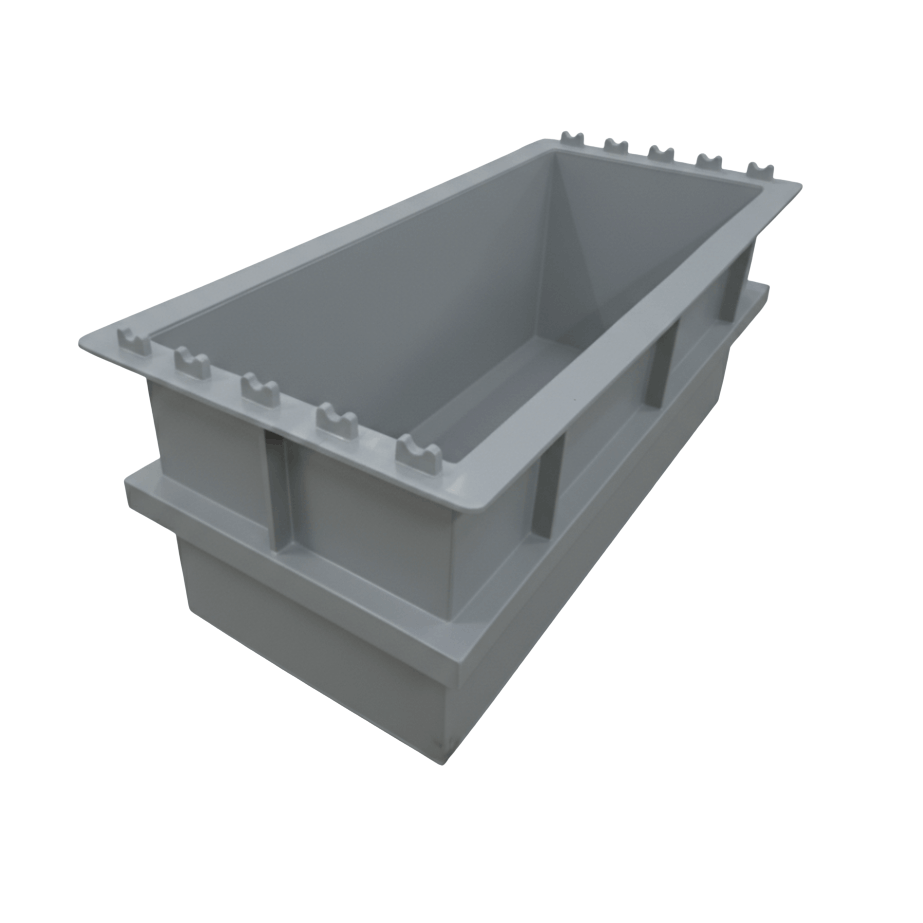

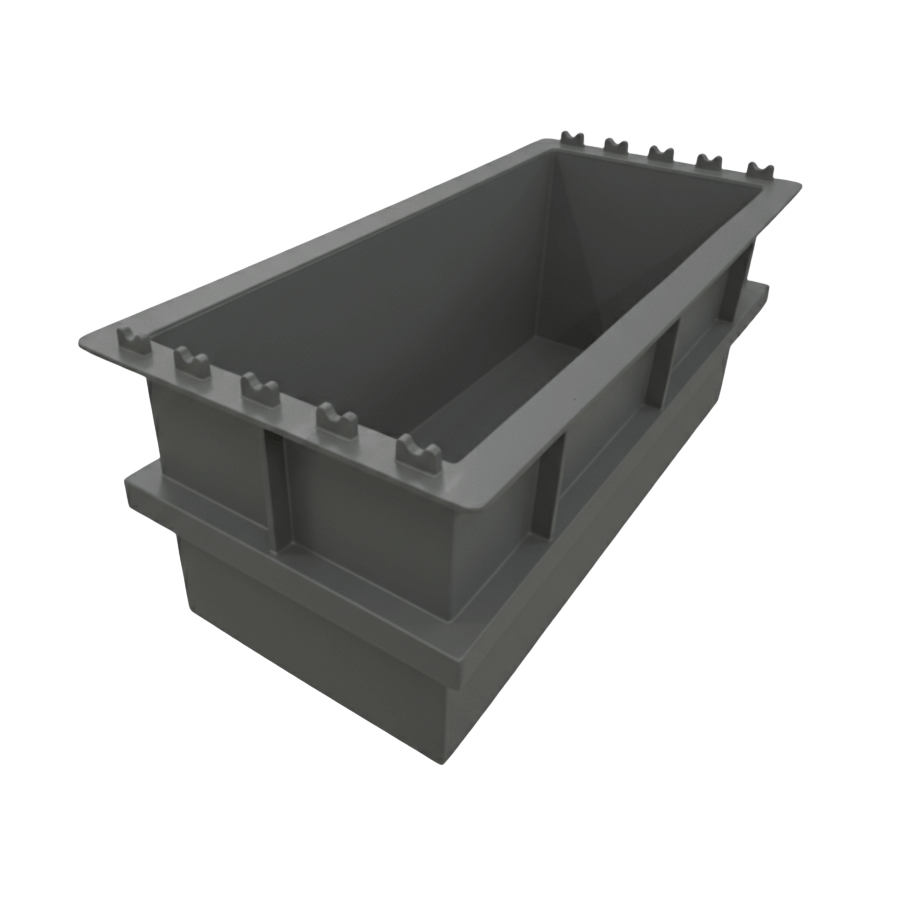

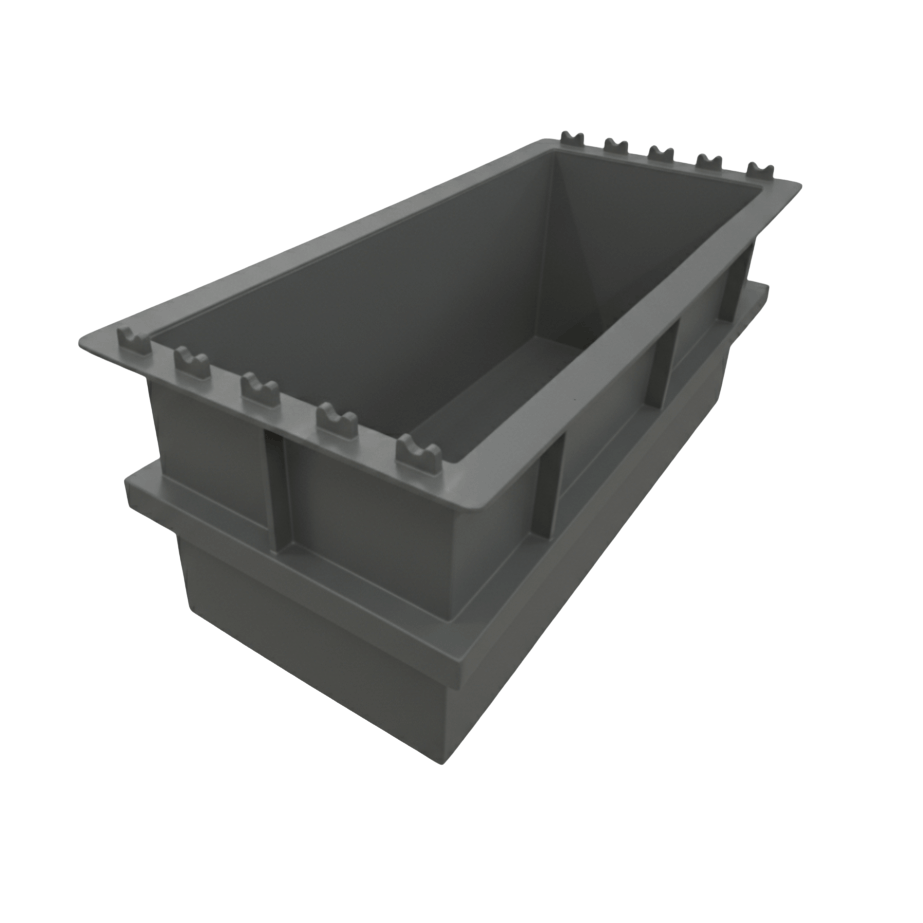

Chemical Storage Tank

Chemical Storage Tank

Corrosion-Resistant Storage Solutions for Industrial Chemicals :

Chemical storage tanks are used for the safe storage of corrosive,

hazardous, and process chemicals in industrial environments. When

metals fail due to corrosion, thermoplastic and composite tanks provide a

reliable alternative with longer service life and lower maintenance.

Our chemical storage tanks are fabricated using thermoplastic and lined

composite constructions, ensuring chemical compatibility, structural

stability, and leak-free performance under continuous service conditions.

These tanks are suitable for indoor and outdoor installations across a wide range of industries.

Material Options & Operating Temperature Ranges :

Chemical storage tanks are designed based on chemical type, storage volume, operating temperature, and structural requirements.

-

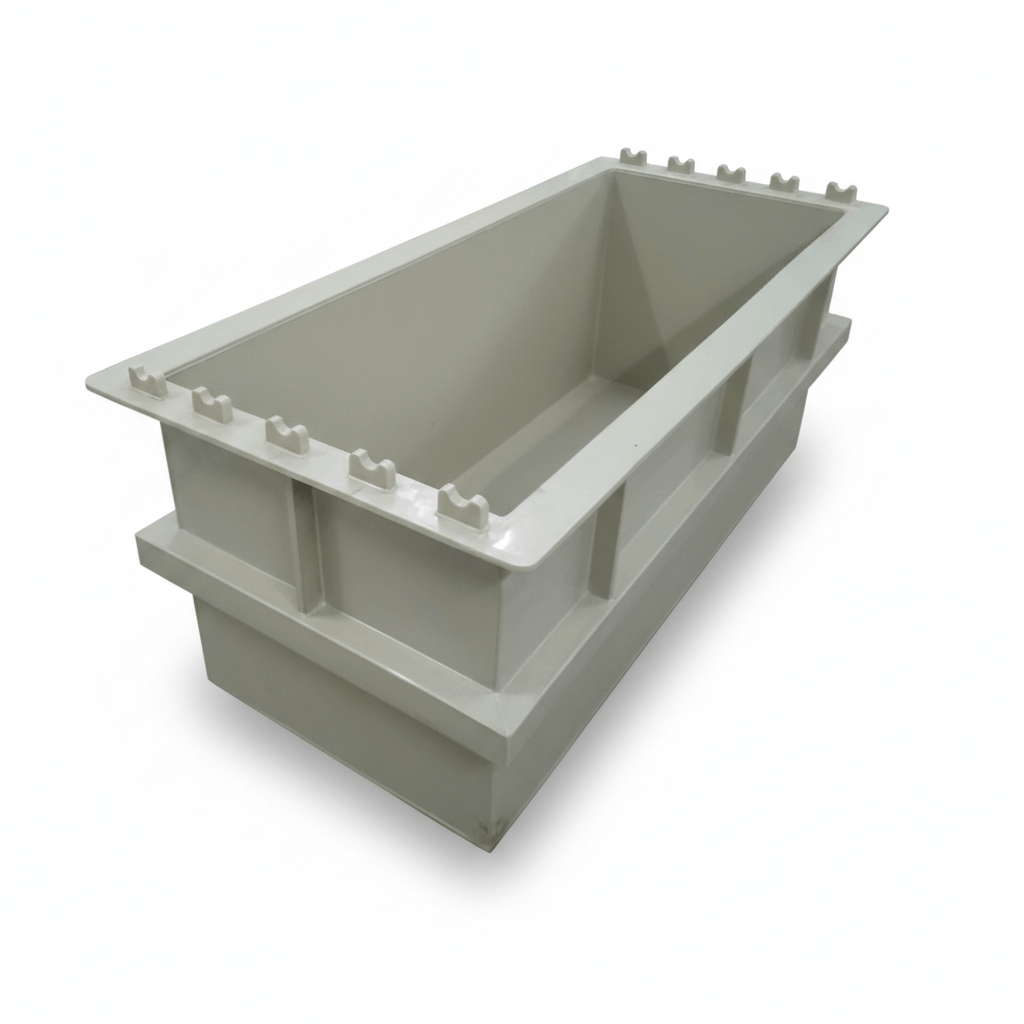

PP (Polypropylene Copolymer) : Used for general chemical storage and utility tanks. Suitable for ambient to moderate temperatures up to 80–90°C, with good impact resistance.

-

PPH (Polypropylene Homopolymer) : Offers higher rigidity and chemical resistance. Commonly used for chemical storage tanks operating up to 90–100°C.

-

PVDF (Polyvinylidene Fluoride) : Selected for highly aggressive and corrosive chemicals. Provides excellent chemical resistance with reliable performance up to 120–150°C, depending on design.

-

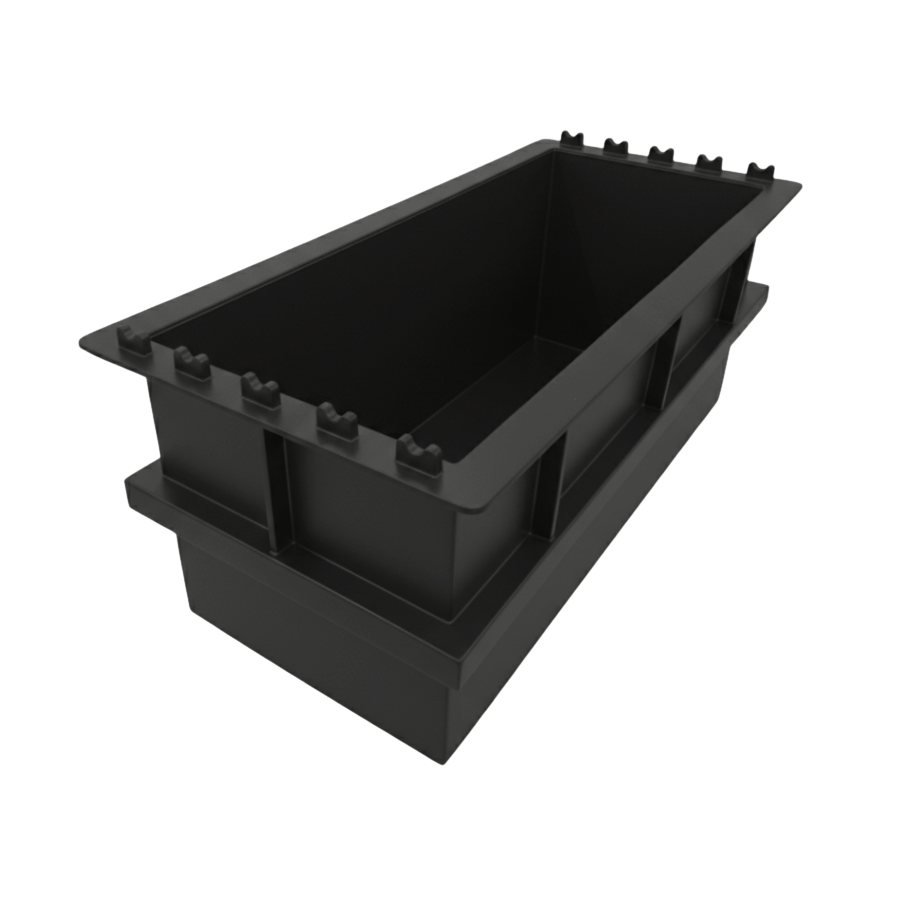

HDPE (High-Density Polyethylene) : Widely used for water, chemicals, and bulk storage. Suitable for ambient temperature applications up to 60–70°C, with good impact and abrasion resistance.

-

PVC (Polyvinyl Chloride) : Used for low-temperature chemical storage. Performs reliably up to 60°C, especially in utility and ventilation-related storage systems.

-

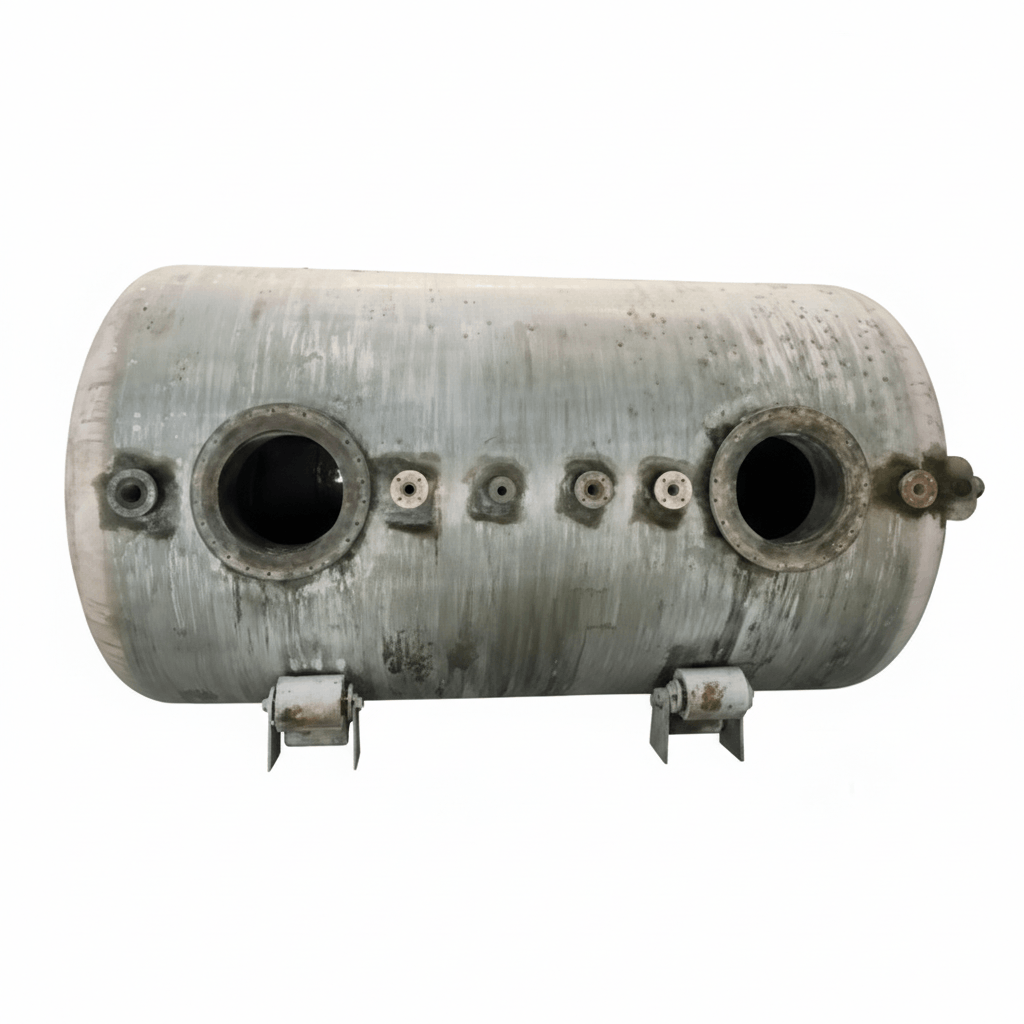

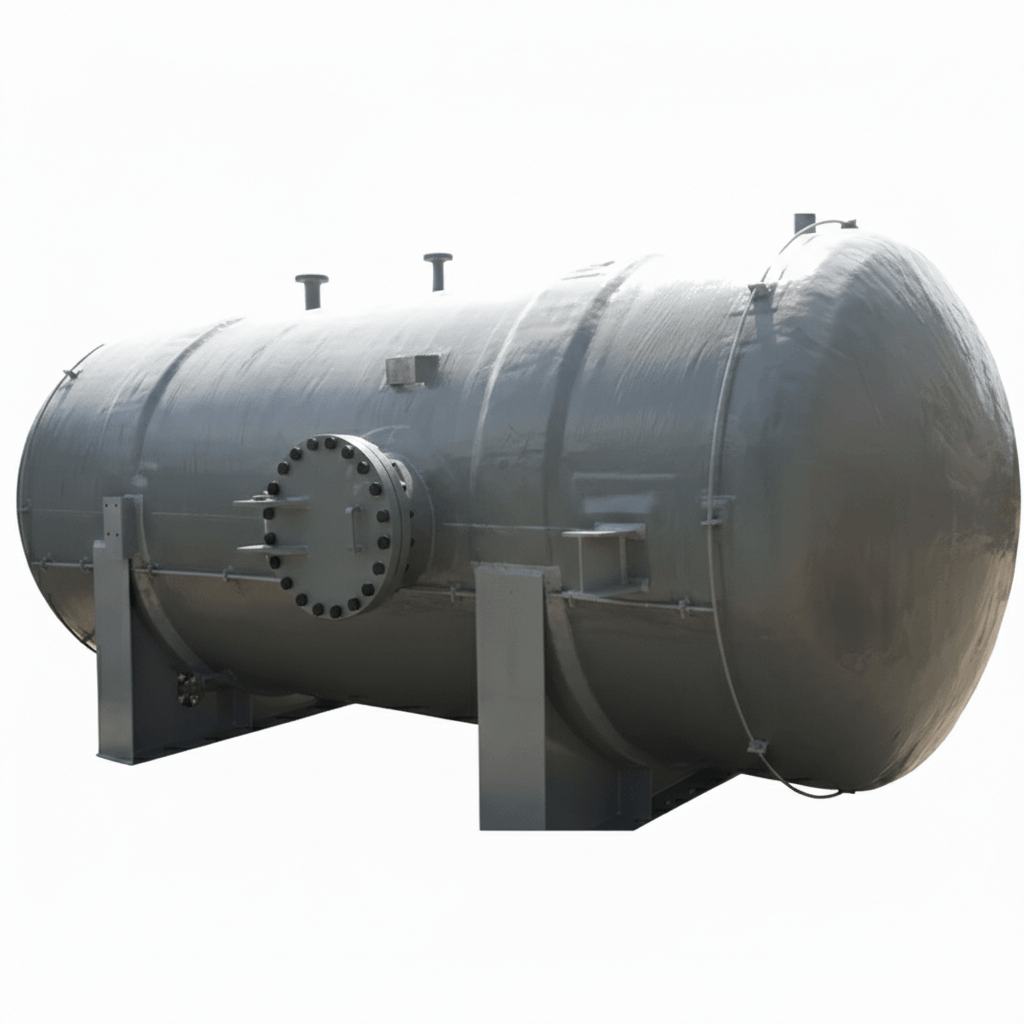

FRP (Fiber Reinforced Plastic) : Provides structural strength and corrosion resistance. Suitable for ambient to moderate temperatures, depending on resin system.

-

PP–FRP Lined Construction : Combines polypropylene’s chemical resistance with FRP’s mechanical strength. Used for larger storage tanks handling corrosive chemicals at moderate temperatures.

-

HDPE–FRP Lined Construction : Offers abrasion resistance with enhanced stiffness. Suitable for ambient temperature chemical storage.

-

MS–FRP Lined Construction : Mild steel provides structural rigidity, while FRP lining protects against corrosion. Used for heavy-duty tanks operating at ambient temperatures.

What Makes Our Chemical Storage Tanks Different :

| Features | Our Advantage | |

|---|---|---|

| Material Construction : | Fabricated using corrosion-resistant thermoplastic and composite materials. | |

| Flow Control Efficiency : | Designed for safe storage of aggressive chemicals. | |

| Internal Surface Finish : | Smooth internal surfaces to prevent contamination and buildup. | |

| Filtration Cycle Durability : | Leak-free welded construction. | |

| Custom Configuration Compatibility : | Suitable for indoor and outdoor installation. | |

Key Advantages :

-

Excellent resistance to corrosion and chemical attack.

-

Long service life compared to metal tanks.

-

Reduced maintenance and downtime.

-

Custom tank sizes and configurations.

-

Lightweight alternatives available for easy installation.

Applications & Industries :

-

Chemical Processing Plants : Storage of acids, alkalis, solvents.

-

Water & Wastewater Treatment : Chemical dosing and storage.

-

Pharmaceutical & Specialty Chemicals : Process and utility chemical storage.

-

Electroplating & Surface Treatment : Storage of corrosive solutions.

-

Industrial Utilities : Bulk and intermediate chemical storage.

Chemical Storage Tank

CPVC Chemical Storage Tank

FRP Chemical Storage Tank

HDPE Chemical Storage Tank

HDPE Spiral Chemical Storage Tank

MS+FRP Chemical Storage Tank

PP Chemical Storage Tank

PPh Chemical Storage Tank

PPH Spiral Chemical Storage Tank

PVC Chemical Storage Tank

PVDF Chemical Storage Tank

UPVC Chemical Storage Tank

Why Industries Choose Us

Engineering Trust. Delivering Quality

-

Expertise in thermoplastic and composite tank fabrication.

-

Multiple material options for chemical compatibility.

-

Proven performance in corrosive environments.

-

Technical support for tank design and material selection.

Request a Quote

Let’s Build Your Next Project

If your application requires chemical storage tanks made from thermoplastic or composite materials, we provide reliable solutions tailored to your operating conditions.