PP Lining

PP Lining

Corrosion-Resistant Protection for Industrial Equipment :

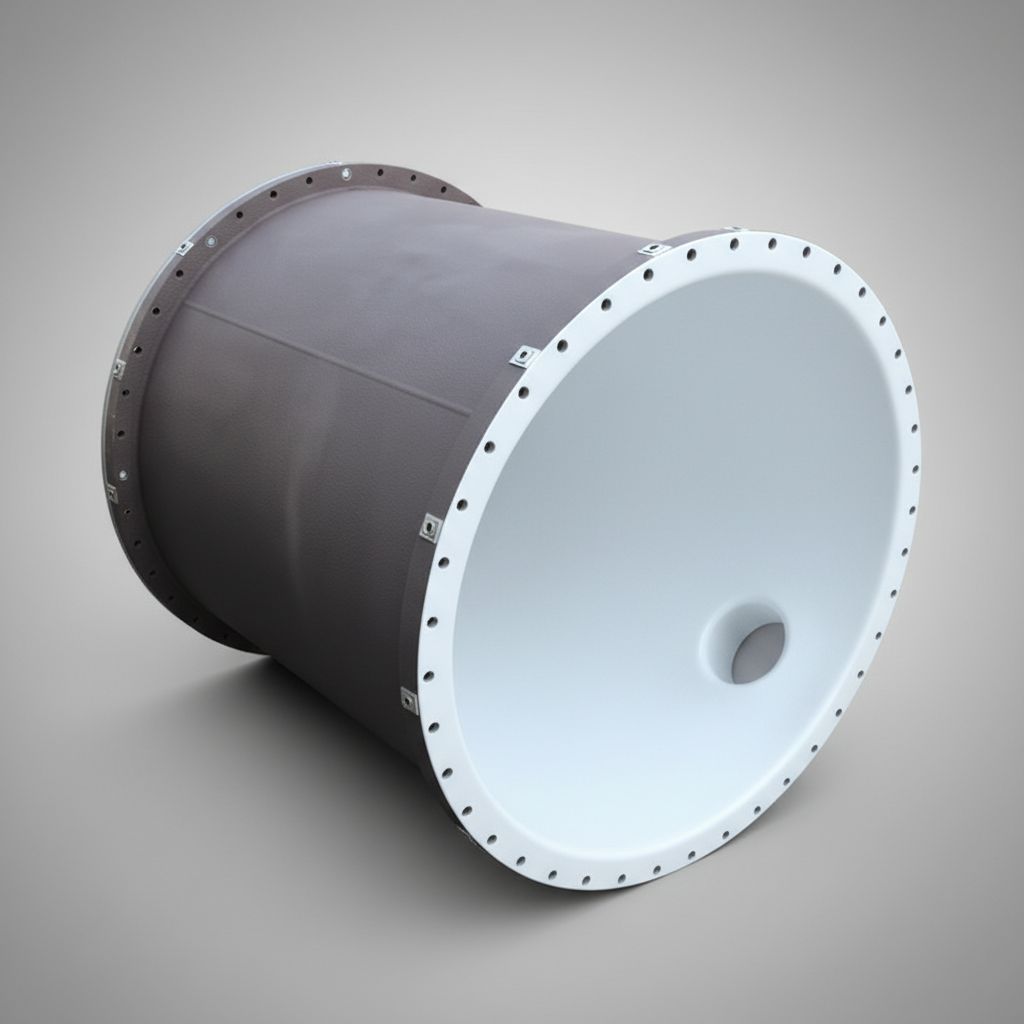

PP (polypropylene) lining is applied inside equipment and structures

where the base material alone cannot withstand aggressive chemicals,

moisture, or abrasion. Made from high-quality polypropylene

thermoplastic, our linings deliver long-lasting performance in

environments exposed to acids, alkalis, solvents, and continuous

mechanical wear.

Polypropylene’s non-reactive nature and resistance to moisture make it

suitable for both, forming composite systems such as

food-grade applications and industrial corrosion

control.Whether protecting tanks, vessels, or containment systems, PP

lining enhances service life while maintaining product purity and reducing maintenance frequency.

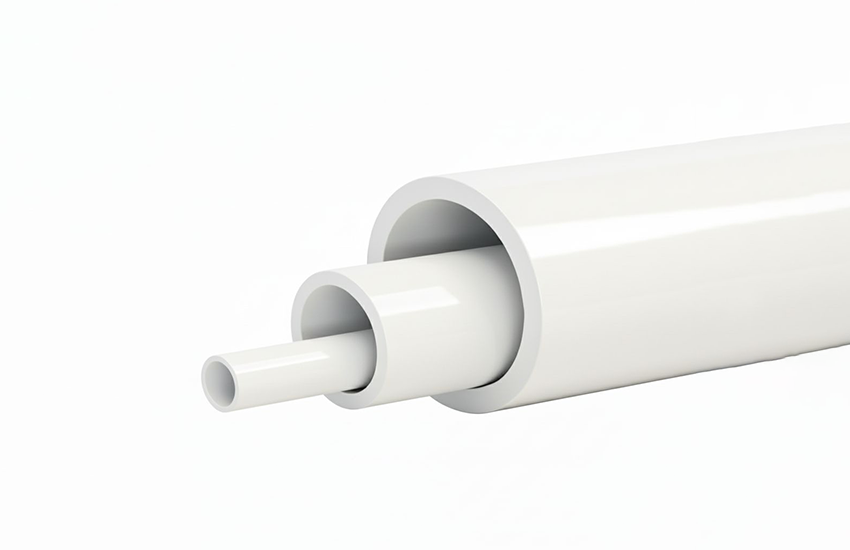

We also provide specialized variations such as MS + PP lining, SS + PP

lining, and FRP + PP liningto suit specific structural materials and

application needs. These combinations allow you to protect Mild Steel (MS),

Stainless Steel (SS), or Fiber-Reinforced Plastic (FRP) substrates with

tailored corrosion-resistant layers.

What Makes Our PP Lining Different :

PP linings may look similar on the surface, but performance depends on material quality, lining thickness, and installation control.

| Features | Our Advantage | |

|---|---|---|

| Material Quality : | High-grade virgin polypropylene with stable chemical resistance. | |

| Uniform Thickness : | Even lining for consistent protection across surfaces. | |

| Non-Reactive Surface : | Minimizes scaling, contamination, and product degradation. | |

| Thermal & Chemical Resistance : | Suitable for dilute acids, alkalis, salts, and cleaning agents. | |

| Strong Bonding/Adhesion : | Secure long-term adherence to metal or base materials with minimal delamination risk. | |

Key Advantages :

-

Highly resistant to acids, alkalis, solvents, and corrosive media.

-

Non-reactive and non-contaminating for sensitive processes.

-

Lightweight and easy to install with precision control.

-

Minimal maintenance and long in-service durability.

-

Suitable for both industrial and food-related applications.

-

Performs in humid, splash, and outdoor environments.

Applications & Industries :

PP lining is widely used where corrosion control and product integrity are critical :

-

Chemical Processing : Tanks, sumps, scrubbers, storage vessels.

-

Water & Wastewater Treatment : Chemical dosing tanks, treatment units, channels.

-

Food & Beverage (Utility Areas) : Non-contact tanks and process equipment.

-

Pollution Control Systems : Ducts, hoods, and exhaust handling equipment.

-

General Industrial Equipment : Containers, trays, and fabricated process components.

PP Lining :

Why Industries Choose Us

Engineering Trust. Delivering Quality

-

Controlled fabrication and installation process.

-

Reliable material performance across chemical environments.

-

Technical support for lining selection and design.

-

Proven use in corrosion-intensive industrial applications.

Request a Quote

Let’s Build Your Next Project

If your equipment needs dependable chemical protection with a practical

cost structure, our PP lining solutions are a reliable choice.

For specifications, application guidance, or project support, connect with

our technical team.