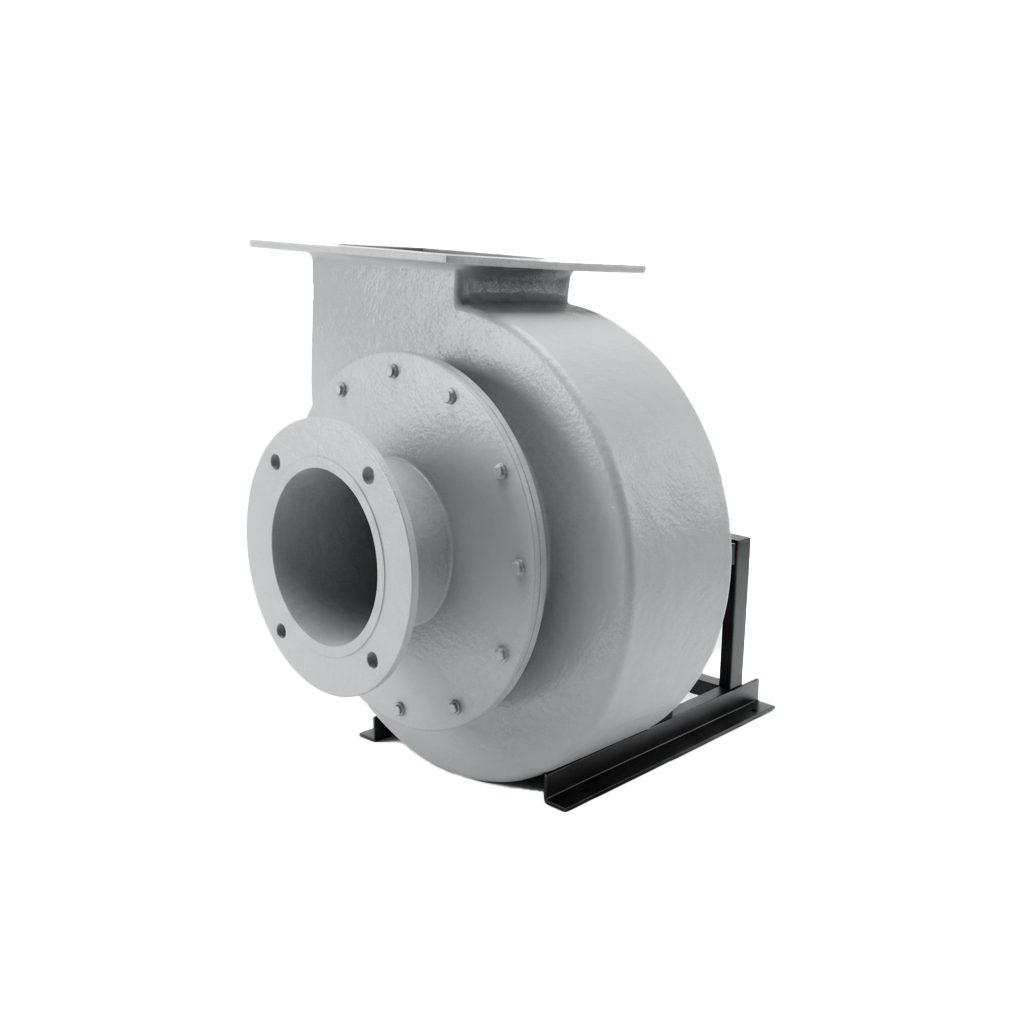

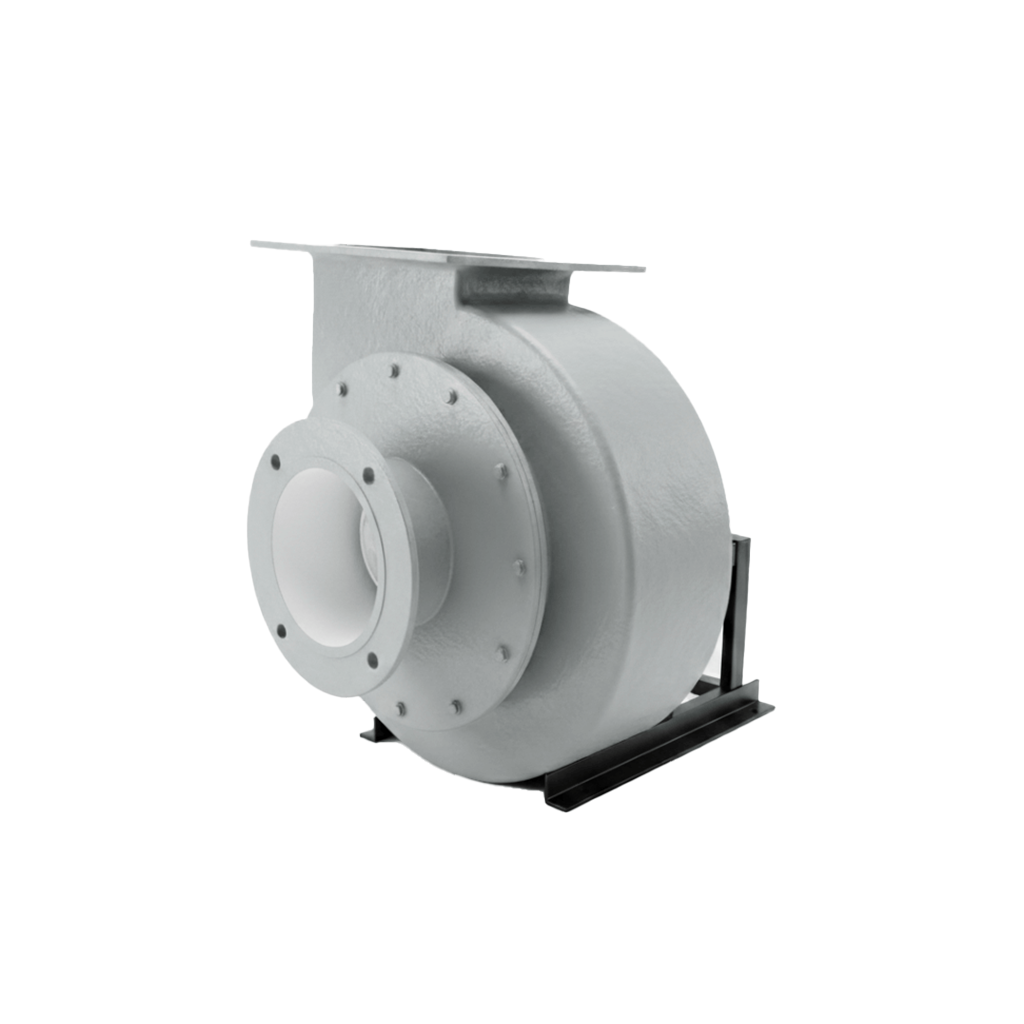

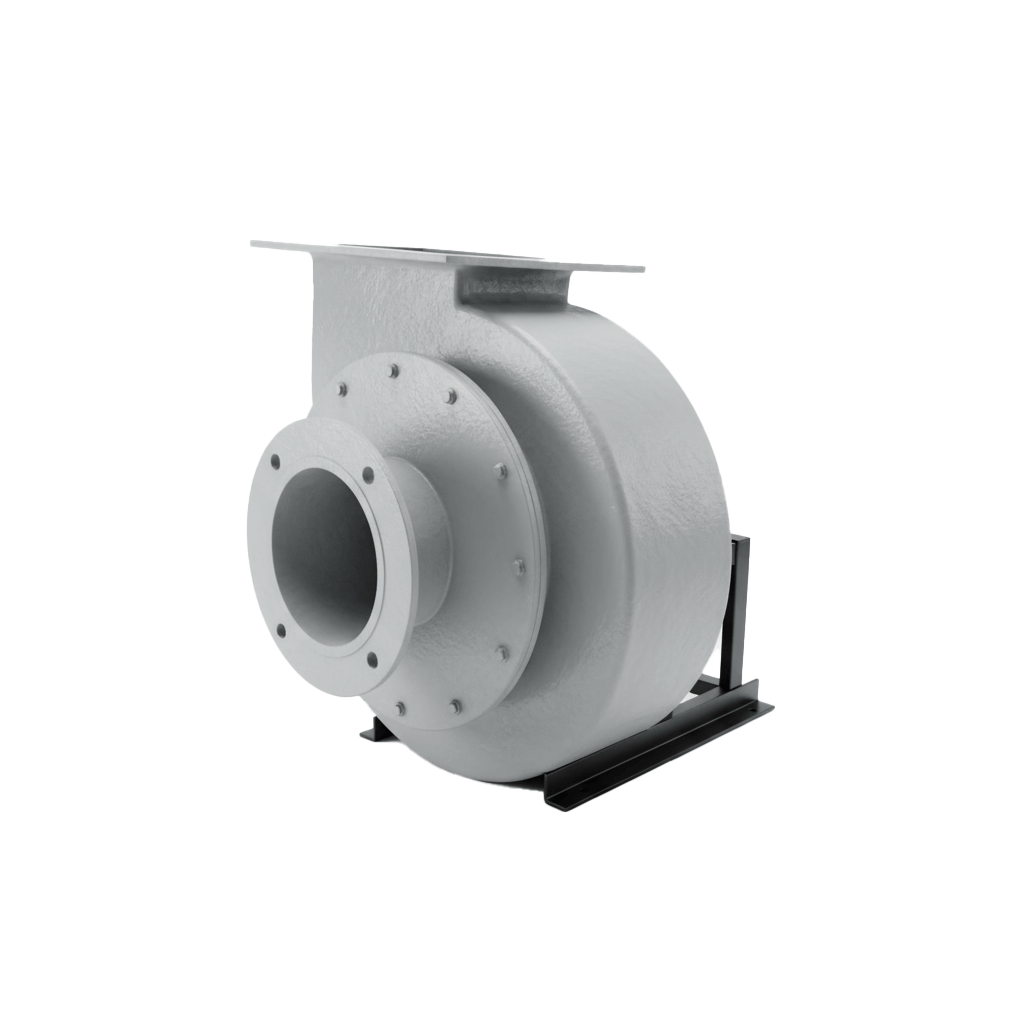

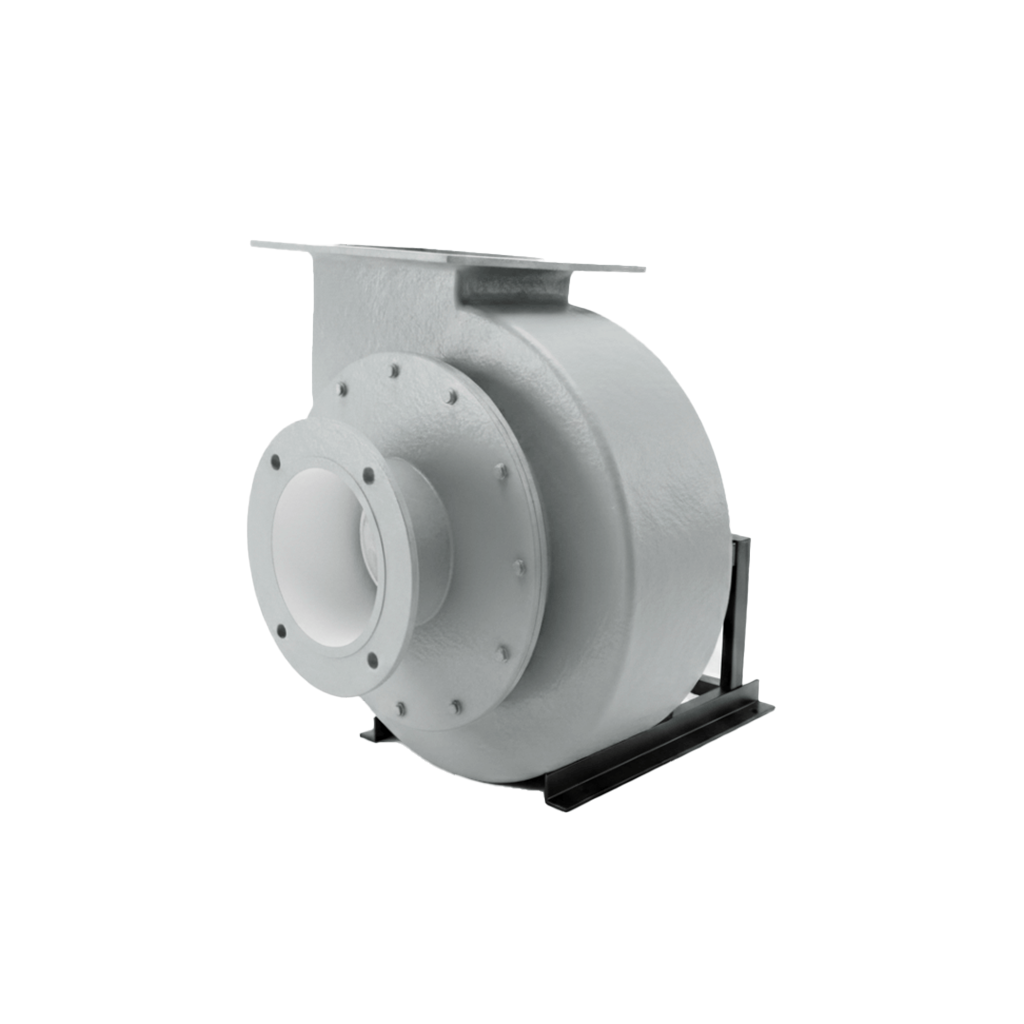

Centrifugal Blowers

Centrifugal Blowers

Corrosion-Resistant Air Handling Solutions for Industrial Applications :

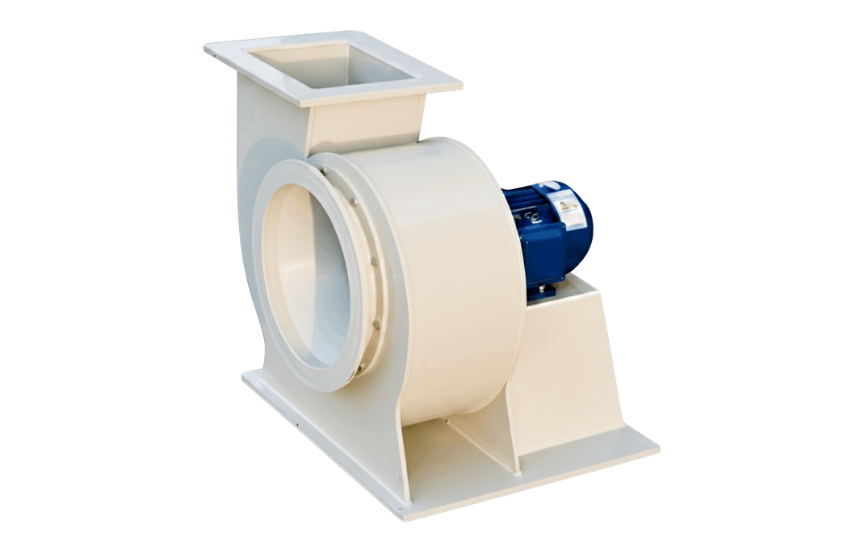

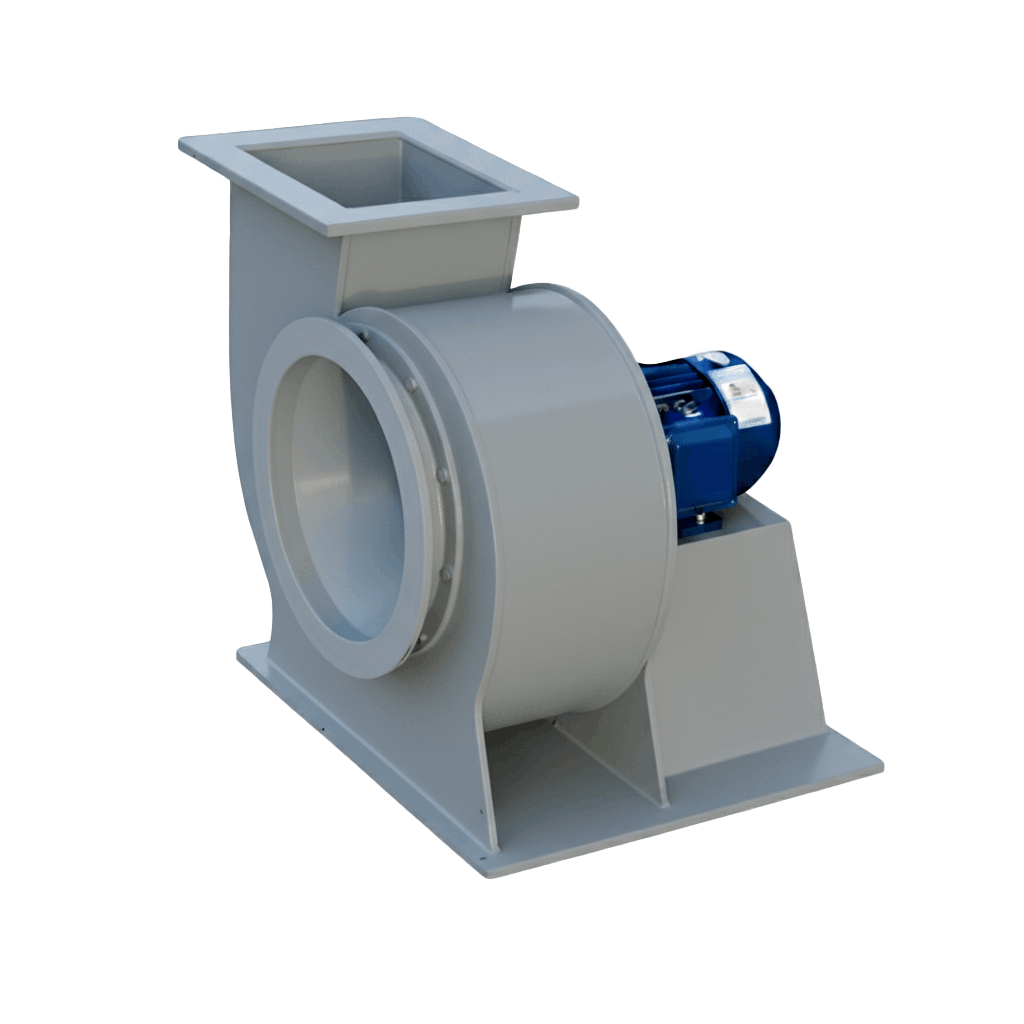

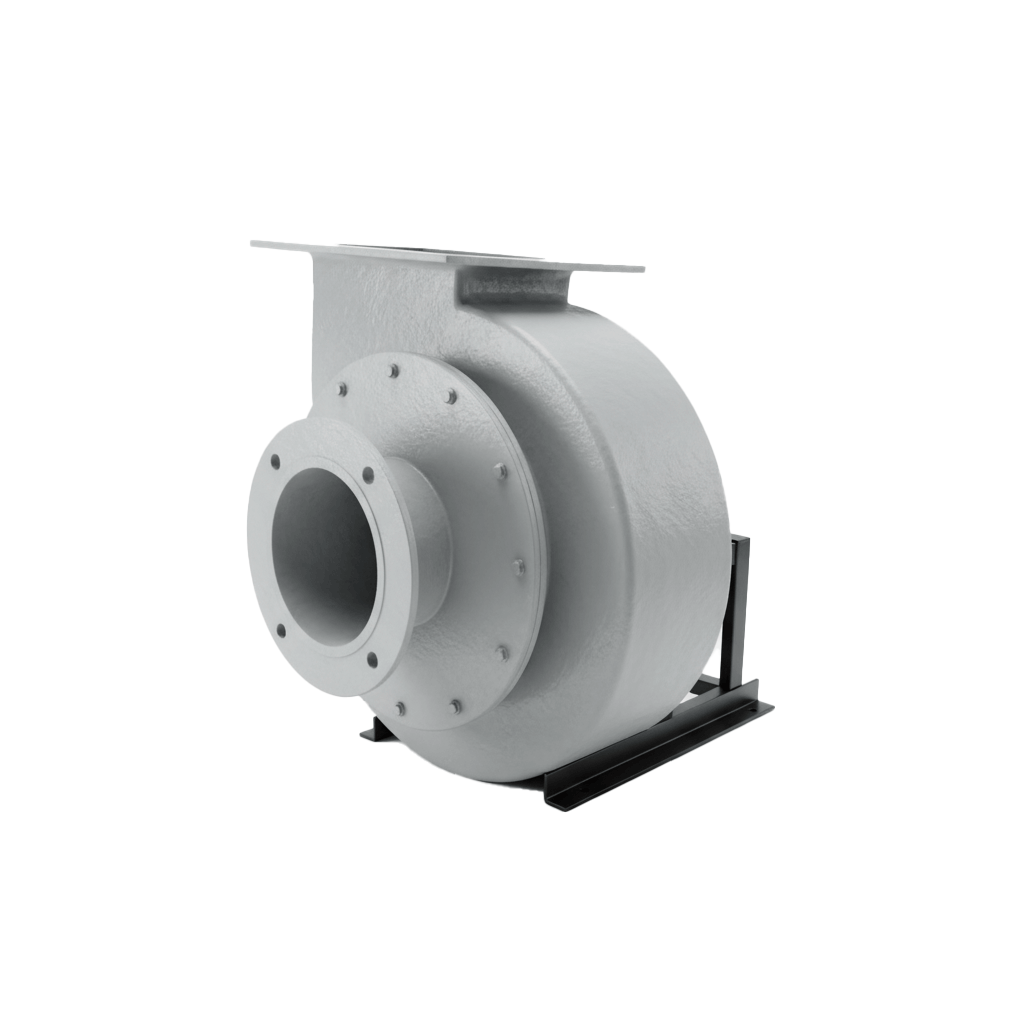

Thermoplastic centrifugal blowers are used for handling corrosive gases,

fumes, and vapors in industrial environments where metal equipment is

prone to rapid corrosion. These blowers are commonly installed in

chemical plants, air pollution control systems, scrubbers, and ventilation

units handling aggressive or moisture-laden air streams.

Manufactured using corrosion-resistant thermoplastic and composite

materials, our centrifugal blowers are designed to deliver stable airflow,

low vibration, and long service life under continuous operating

conditions.

Material Options & Operating Temperature Ranges :

Centrifugal blowers are fabricated using different material combinations based on chemical exposure, operating temperature, and structural requirements.

-

PP (Polypropylene Copolymer) : Used for general ventilation and mildly corrosive fumes. Suitable for ambient to moderate temperatures up to 80–90°C, with good impact resistance and fabrication flexibility.

-

PPH (Polypropylene Homopolymer) : Offers higher rigidity and chemical resistance than PP. Commonly selected for chemical exhaust systems operating up to 90–100°C.

-

PVDF (Polyvinylidene Fluoride) : Preferred for highly corrosive gases and aggressive chemical vapors. Provides excellent chemical resistance with reliable performance up to 120–150°C, depending on design.

-

HDPE (High-Density Polyethylene) : Suitable for low-pressure air handling and moist environments. Recommended for ambient temperature applications up to 60–70°C, especially where abrasion resistance is required.

-

PVC (Polyvinyl Chloride) : Used for low-temperature corrosive gas handling. Performs well up to 60°C, commonly applied in ventilation and scrubber exhaust systems.

-

FRP (Fiber Reinforced Plastic) : Used where higher structural strength is required along with corrosion resistance. Suitable for ambient to moderate temperatures, depending on resin system.

-

PP–FRP Lined Construction : Combines the chemical resistance of polypropylene with the structural strength of FRP. Used for larger blowers handling corrosive fumes at moderate temperatures.

-

HDPE–FRP Lined Construction : Provides abrasion resistance of HDPE with added stiffness from FRP backing. Suitable for ambient temperature air handling in corrosive environments.

-

MS–FRP Lined Construction : Mild steel provides mechanical strength, while FRP lining protects against corrosion. Used for heavy-duty blower housings operating at ambient temperatures with corrosive gases.

What Makes Our HDPE Lining Different :

HDPE lining performance depends on material quality and thickness uniformity. We focus on controlled fabrication and consistent application to ensure reliable long-term protection.

| Features | Our Advantage | |

|---|---|---|

| Material Construction : | Fabricated entirely from corrosion-resistant thermoplastic and composite materials. | |

| Flow Control Efficiency : | Designed for continuous operation in chemical environments. | |

| Internal Surface Finish : | Balanced impeller design for smooth airflow and low vibration. | |

| Filtration Cycle Durability : | Lightweight construction compared to metal blowers. | |

| Custom Configuration Compatibility : | Reduced maintenance and longer service life. | |

Key Advantages :

-

Excellent resistance to corrosive fumes and vapors.

-

No rusting, scaling, or chemical degradation.

-

Stable airflow and pressure performance.

-

Lower operating and maintenance costs.

-

Custom material selection based on process conditions.

Applications & Industries :

-

Chemical Processing Plants : Process exhaust and fume handling.

-

Air Pollution Control Systems : Gas extraction and treatment.

-

Scrubbers & Ducting Systems : Corrosive vapor handling.

-

Electroplating & Surface Treatment : Acidic and chemical fumes.

-

Wastewater Treatment Plants : Odor control and ventilation.

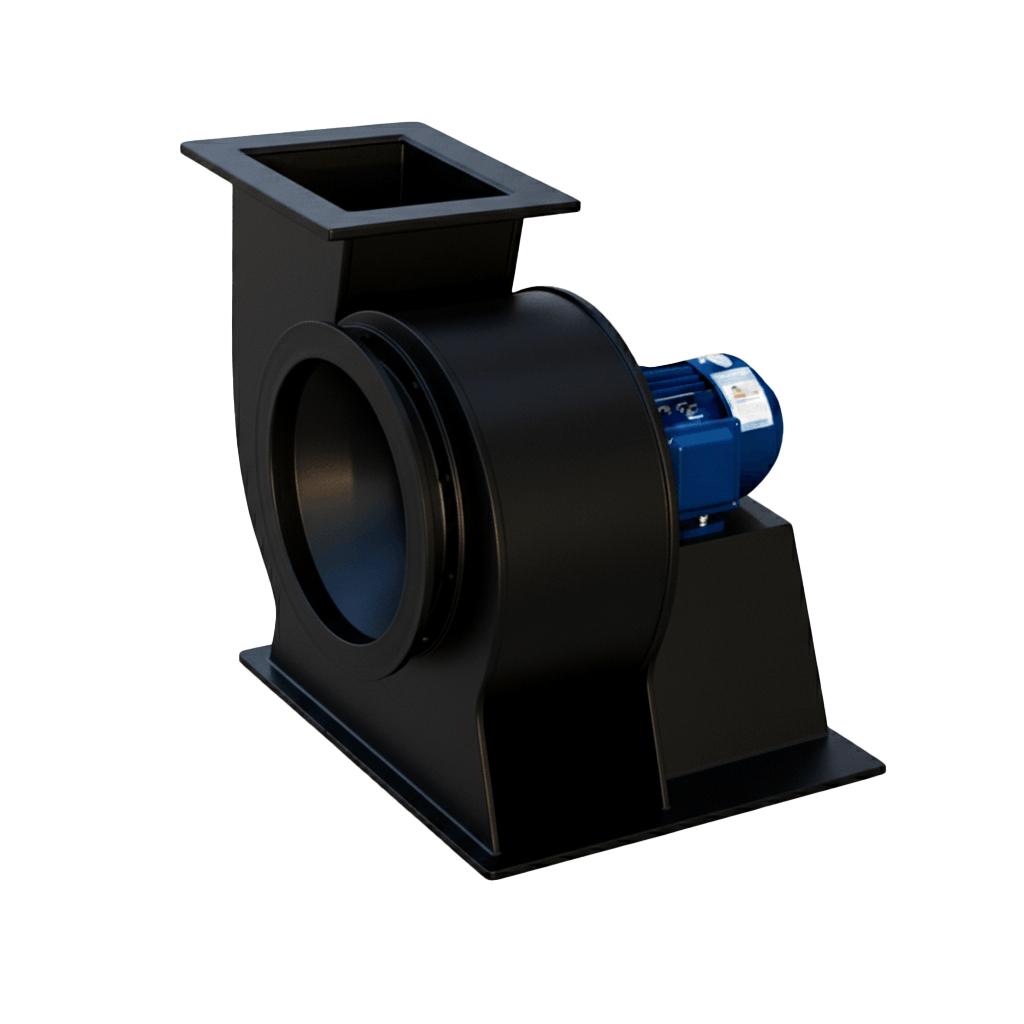

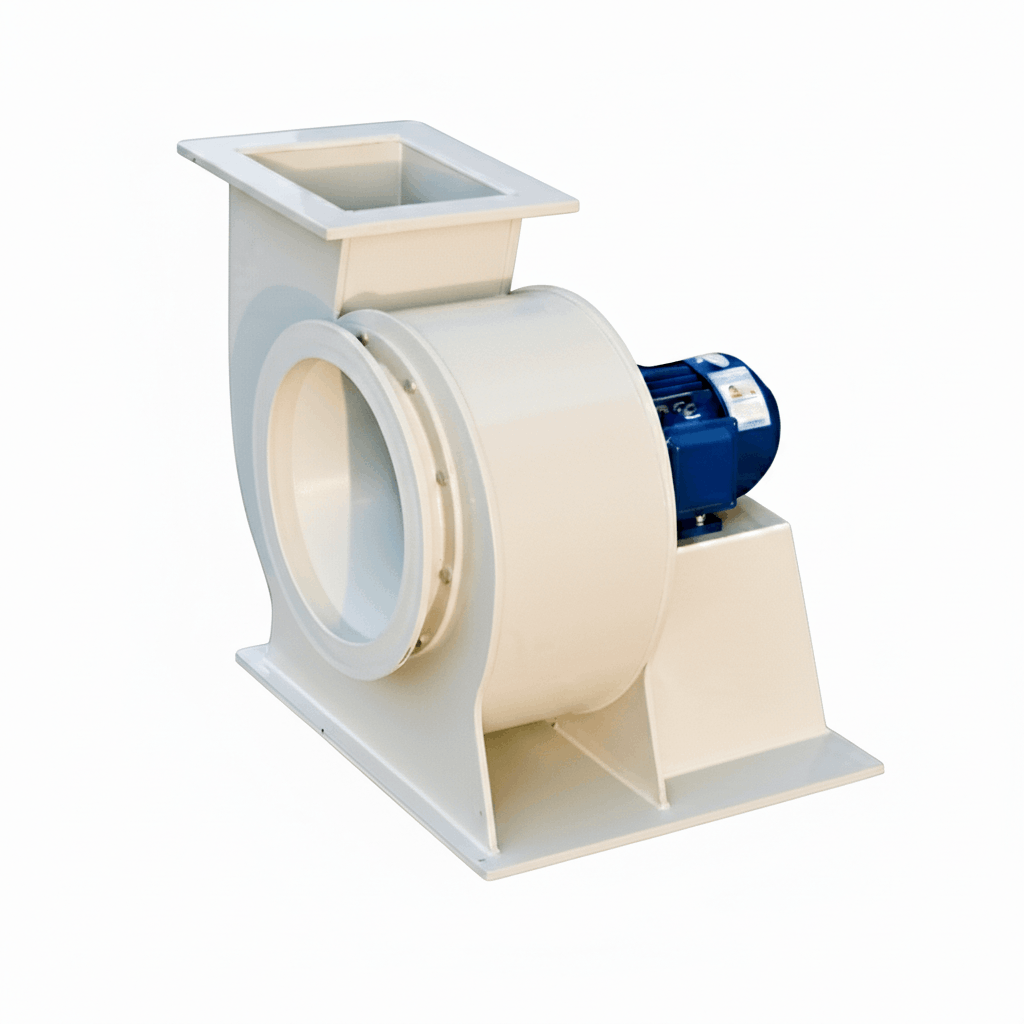

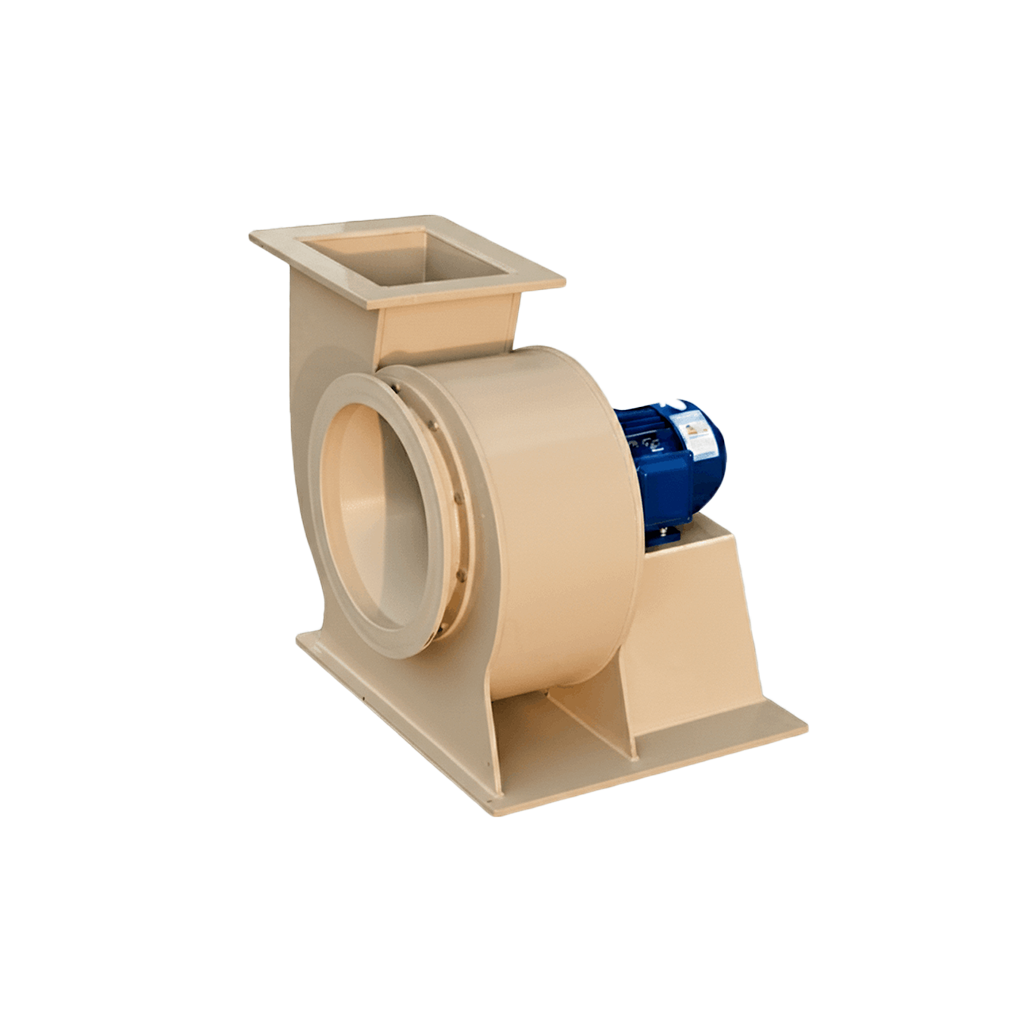

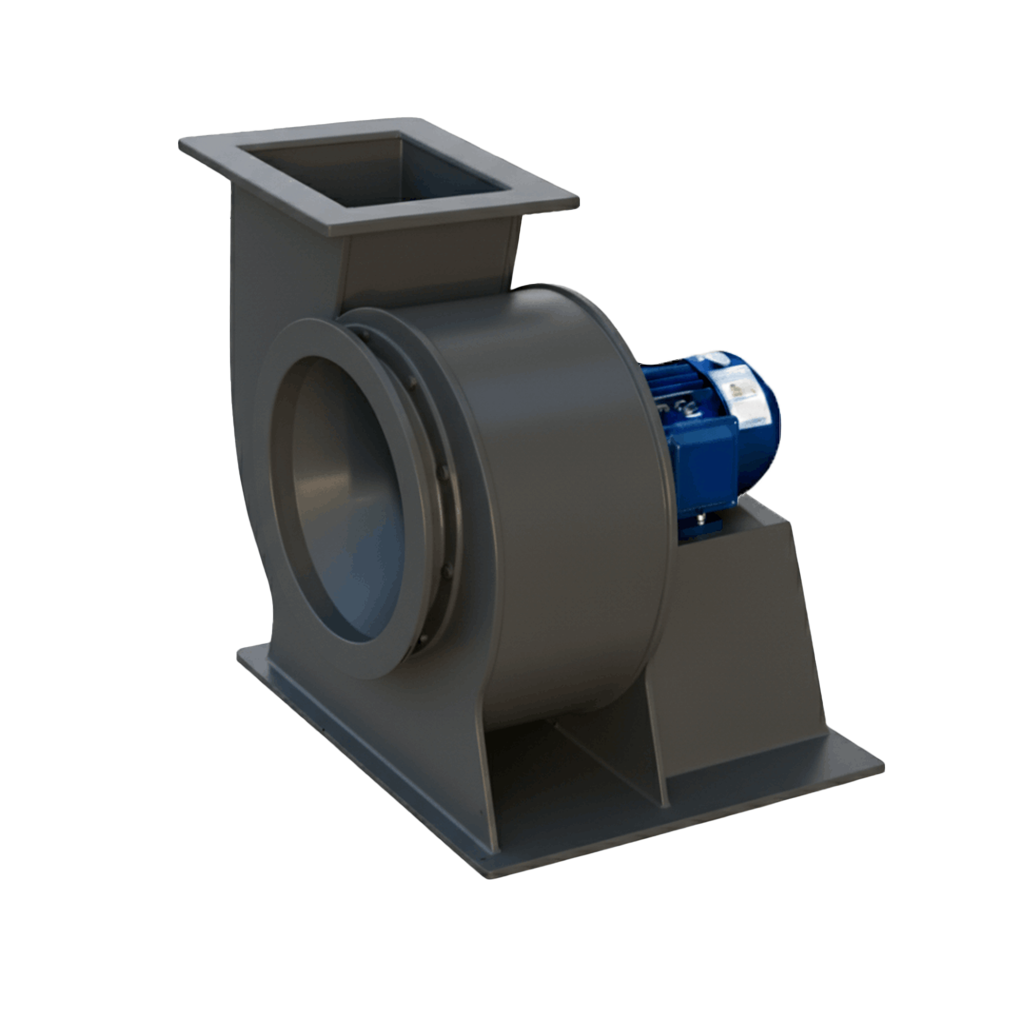

Centrifugal Blowers

CPVC Centrifugal Blower

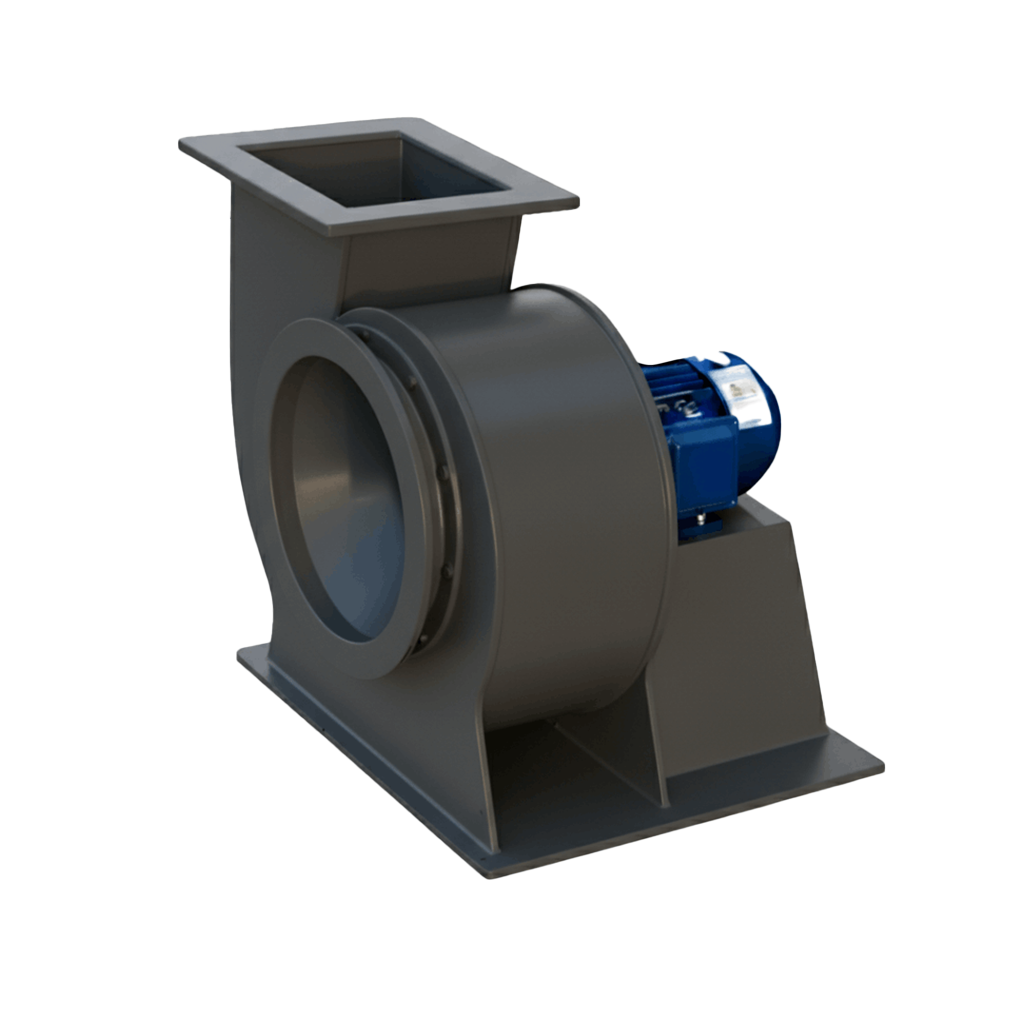

FRP Centrifugal Blower

HDPE Centrifugal Blower

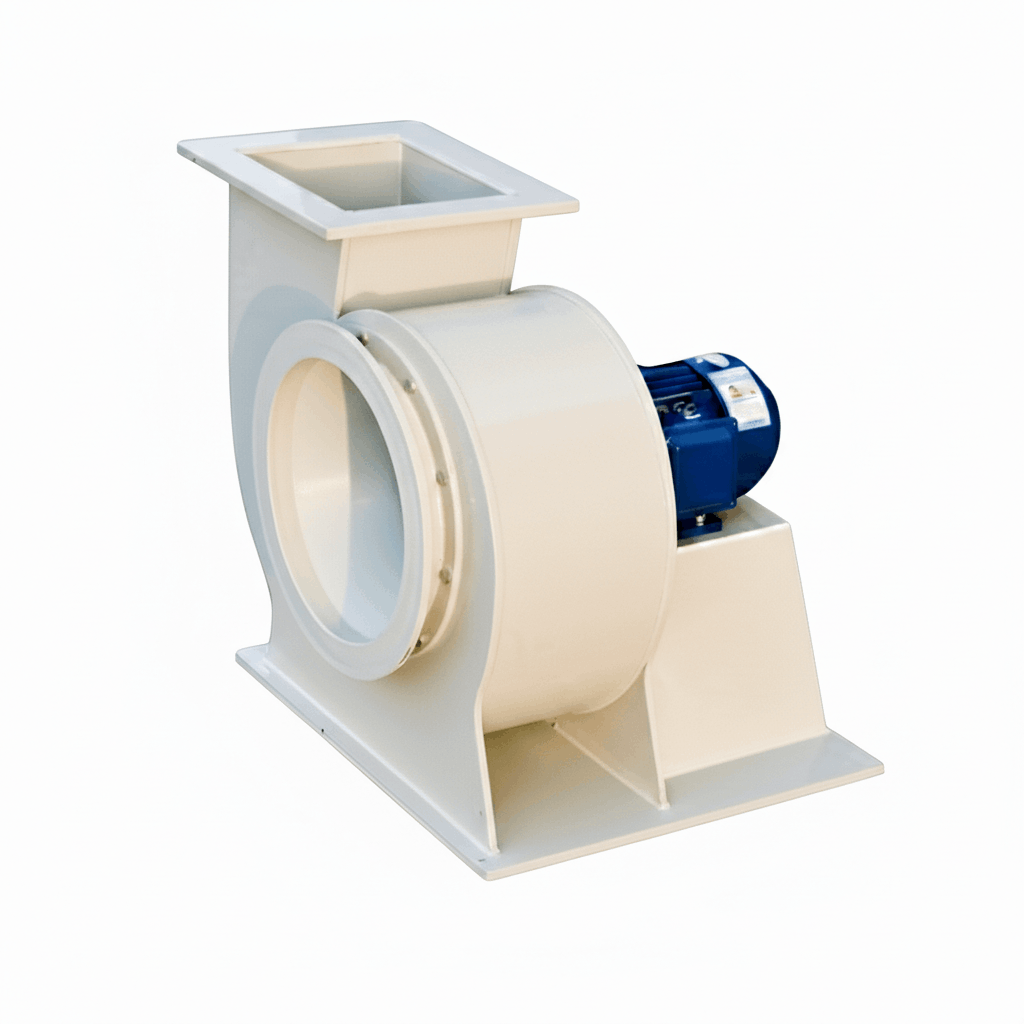

PP Centrifugal Blower

PPH Centrifugal Blower

PVC Centrifugal Blower

PVDF Centrifugal Blower

UPVC Centrifugal Blower

CPVC-FRP Lined Centrifugal Blower

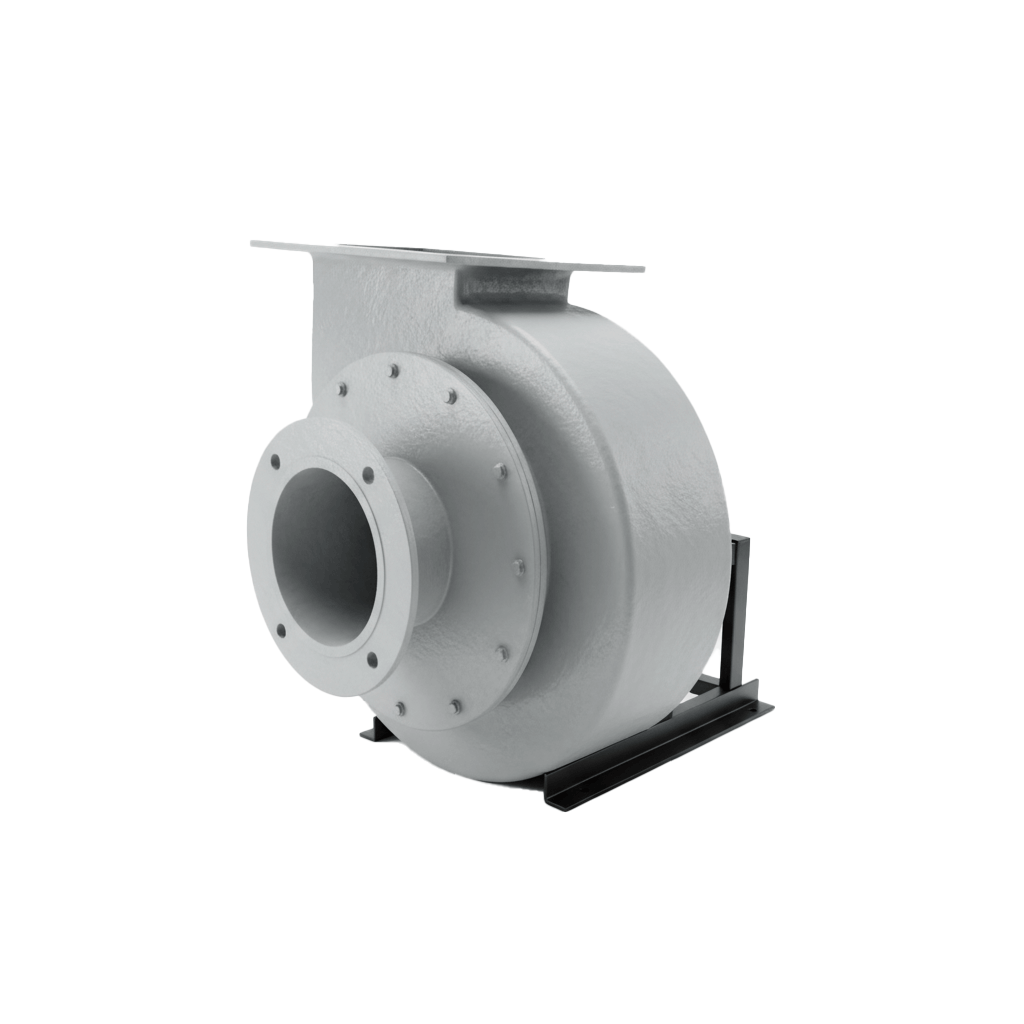

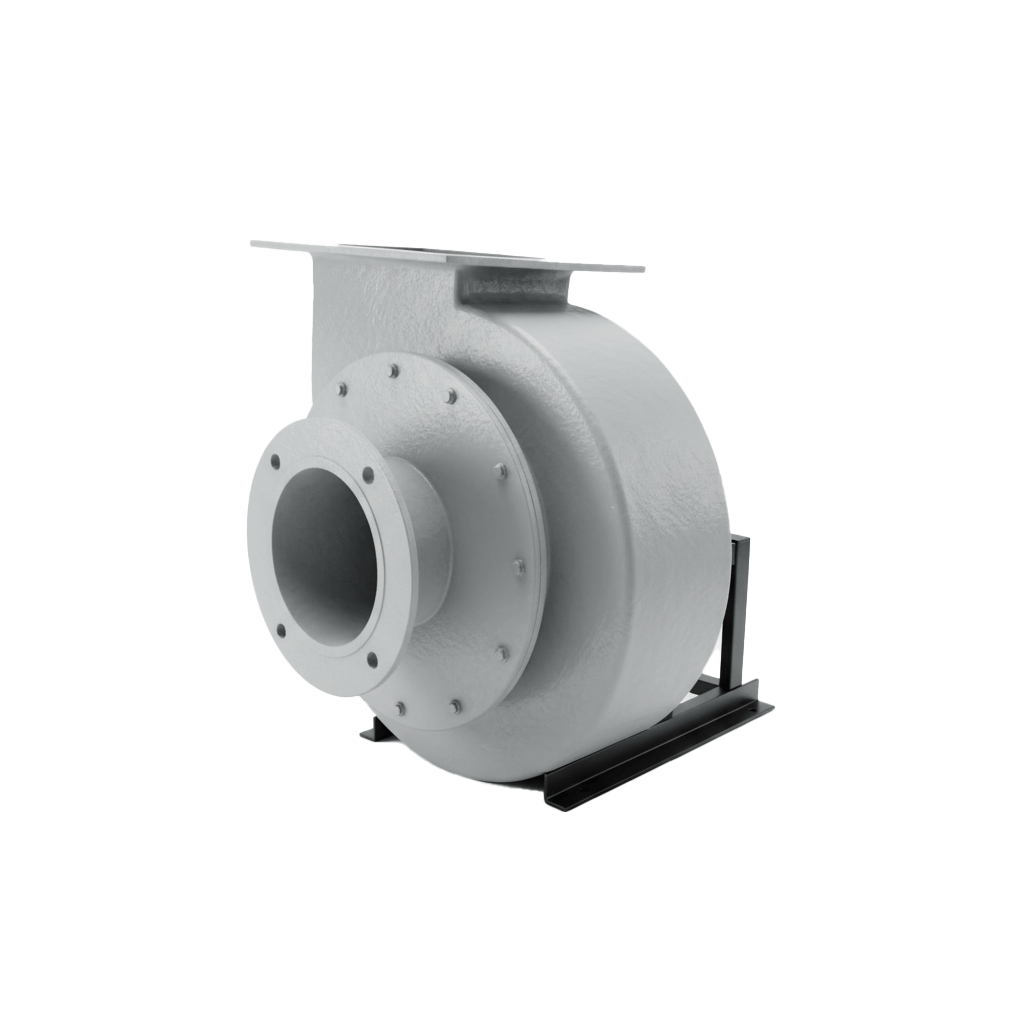

HDPE-FRP Lined Centrifugal Blower

MS-FRP Lined Centrifugal Blower

PP-FRP Lined Centrifugal Blower

PVC-FRP Lined Centrifugal Blower

PVDF-FRP Lined Centrifugal Blower

Why Industries Choose Us

Engineering Trust. Delivering Quality

-

Expertise in thermoplastic and composite fabrication.

-

Multiple material options to suit process requirements.

-

Proven performance in corrosive air handling applications.

-

Technical support for blower selection and system design.

Request a Quote

Let’s Build Your Next Project

If your application requires thermoplastic centrifugal blowers for corrosive air handling, we offer reliable solutions tailored to your operating conditions.