PPH Fittings & Valves

PPH Fittings & Valves

Dependable Connections for Chemical and Utility Piping Systems :

PPH fittings and valves are designed for fluid handling systems that

require chemical resistance, mechanical stability, and reliable performance

under pressure. Manufactured from 100% virgin polypropylene

homopolymer (PPH) , these components are widely used in chemical

processing, water treatment, food utilities, and industrial service lines.

PPH offers strong resistance to acids, alkalis, and many industrial

chemicals, along with good thermal stability for operating temperatures

up to 95–100°C . Its low density and rigidity make fittings and valves

lightweight, easy to install, and suitable for long-term use without

corrosion or scaling.

What Makes Our PPH Fittings & Valves Different :

While many fittings appear similar, performance depends on material quality, dimensional accuracy, and joint reliability.

| Features | Our Advantage | |

|---|---|---|

| Virgin PPH Material : | Manufactured using 100% virgin PPH resin with no regrind or fillers. | |

| Dimensional Consistency : | Accurate molding for proper fitment and secure joints. | |

| Smooth Internal Surfaces : | Reduces pressure loss, buildup, and flow disturbance. | |

| Chemical & Thermal Stability : | WSuitable for aggressive media and elevated service temperatures. | |

| Reliable Joint Performance : | Compatible with butt fusion, socket fusion, and flange connections. | |

Each fitting and valve is produced under controlled conditions to ensure stable performance and predictable installation in piping systems.

Key Advantages :

-

High resistance to corrosion, rust, and chemical attack.

-

Lightweight and easy to handle during installation.

-

Good mechanical strength under pressure and stress.

-

Non-toxic and suitable for food-contact and utility applications.

-

Good electrical insulation properties.

-

Long service life with low maintenance requirements.

Applications & Industries :

PPH fittings and valves are commonly used in:

-

Chemical Processing : Chemical transfer lines, dosing systems, tanks, and pump connections.

-

Water & Wastewater Treatment : Effluent pipelines, filter systems, neutralization units.

-

Food & Beverage Utilities : Wash-down lines, non-contact process piping.

-

Battery & Electronics Manufacturing : Chemical tanks, covers, and fluid handling components.

-

Industrial Utilities : Cooling water, ventilation, and service pipelines.

Fittings & Valves

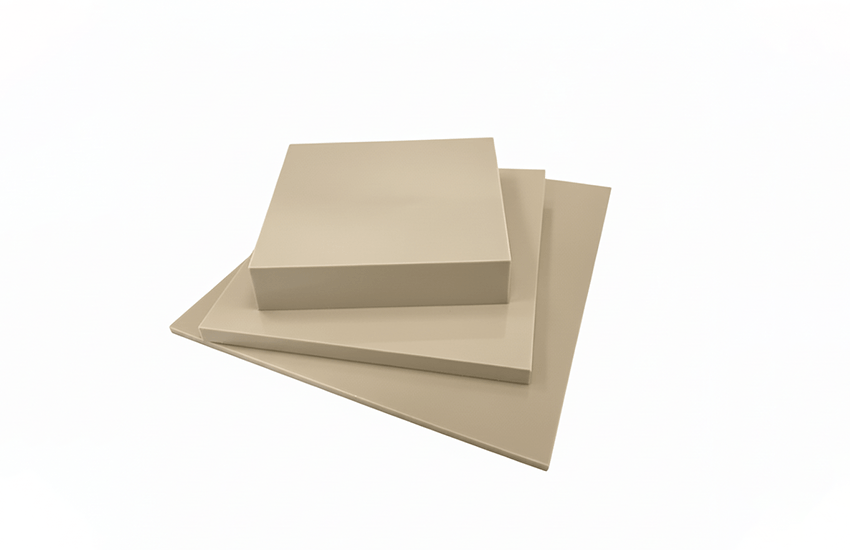

Blind Flange

Cross Tee

Elbow-45deg

Elbow-90deg

Equal Tee

Reducer

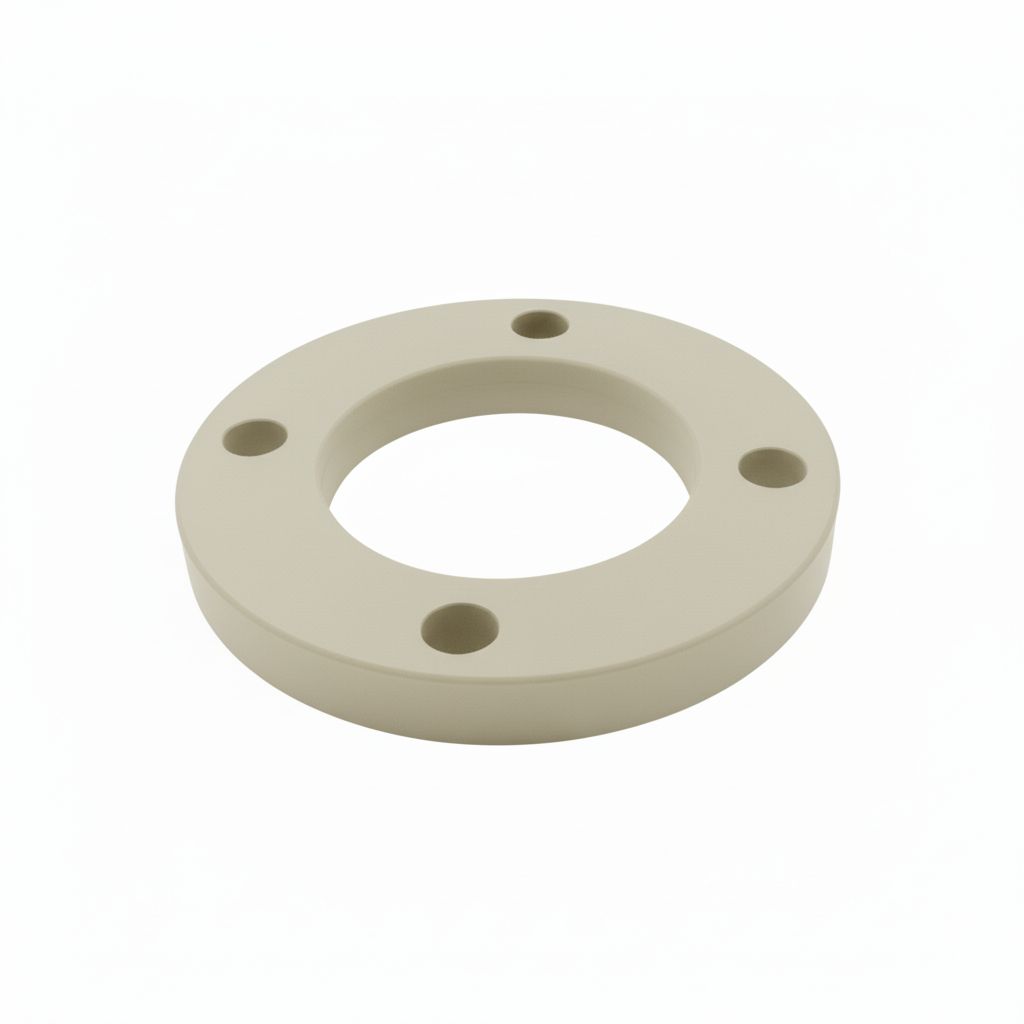

Slip-on Flange

Stub End Pipe

Un Equal Tee

Van Stone Flange

Blind Flange

Slip-On Flange

Van Stone Flange

Cross Tee

Elbow-45deg

Elbow-90deg

End-Cap

Equal Tee

Female Threaded Adapter

Male Threaded Adapter

Reducer

Socket Coupler

Long Neck Stub-End Pipe-End

Un-Equal Tee

Union

Short Neck Stub-End Pipe-End

Tail Piece Flange

3 Way Union Type Valve

Ball Valve Flang End

Butterfly Valve

Diaphragm Valve Flang End

Foot Valve Flang End

Globe Valve Flang End

Non Return Valve Flang End

Sight Glass Flang End

Swing Type Check Valve

True Union Ball Valve

True Union Type Ball Valve Flang End

Union Type Check Valve

Why Industries Choose Us

Engineering Trust. Delivering Quality

-

Consistent raw material quality and controlled molding.

-

Reliable fitment and fusion compatibility.

-

Support for material selection and system design.

-

Proven use across chemical and utility applications.

Request a Quote

Let’s Build Your Next Project

Your systems deserve piping fittings and valves that performs as reliably as your process. For specifications, sizing, or application support, connect with our technical team.